Some Ideas on Retaining Wall Inspections You Should Know

Wiki Article

The Single Strategy To Use For Retaining Wall Inspections

Table of ContentsLittle Known Questions About Retaining Wall Inspections.The 6-Minute Rule for Retaining Wall InspectionsHow Retaining Wall Inspections can Save You Time, Stress, and Money.Retaining Wall Inspections Can Be Fun For AnyoneRetaining Wall Inspections Can Be Fun For Anyone

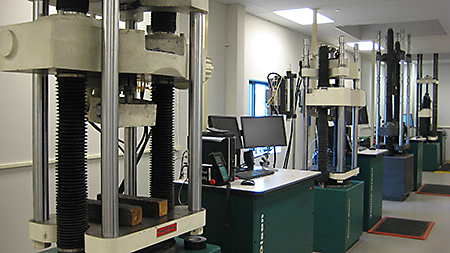

, Carbon-Fiber, Ceramic Matrix Composites, Titanium, Polymers, Common Steels, 4340 Steel, Stainless Steels, A2 Device Steel, Inconel 718, Aluminum 7050, and Aluminum Lithium 2195, as well as several others., completed products and components consisting of light weight aluminum spreadings and also extrusions.At Westmoreland Mechanical Testing & Research, Inc (WMT&R) Stress and also Compression examinations are conducted on an impressive series of makers with abilities from 10 grams to 1,000,000 pounds. Checking is performed in various atmospheres (Argon, Vacuum, Corrosive Mediums) at cryogenic, ambient, and also elevated temperature levels (-450 F to +2200 F). Our exclusive screening software program offers the ability to run common tests plus complete stress/full pressure examinations at numerous strain prices, crosshead speeds, tons ranges, and strain ranges as your needs need.

WMT&R evaluates the procedure of modern localized permanent structural adjustment occurring in a product subjected to problems that generate changing stress and anxieties as well as pressures at some point or factors. These stresses and strains may culminate in splits or complete fracture after an enough number of fluctuations. WMT&R has a huge variety of device and also fixtures efficient in custom configurations and also components.

Retaining Wall Inspections Things To Know Before You Get This

Temperature level and creep readings are videotaped by computers as well as constantly kept track of to guarantee the utmost precision. Mechanical Design, The Mechanical Engineering laboratory at Westmoreland Mechanical Testing & Study, Inc (WMT&R) is staffed by specialists as well as designers in product examination of real model components and subassemblies.

Factory The high-technology, full-service Equipment Store at Westmoreland Mechanical Screening & Research Study, Inc (WMT&R) incorporates a tidy, temperature-controlled environment, modern equipment, and the ability to equipment all test specimens onsite. In addition to machining standard specimens, our Factory can custom-design as well as equipment fixtures for testing ended up components, weird forms, and also difficult or exotic materials.

The Best Guide To Retaining Wall Inspections

With innovative in-house capacities, as well as considerable engineering experience, WMT&R are experts in low-stress grinding and machining sub dimension specimens to very close tolerances. Thermal Evaluation refers to the selection of strategies established as well as utilized in which any physical home of a given product/system is continuously gauged as a feature of temperature.WMT&R utilizes numerous methods including; Dilatometry (DIL), Laser Flash Evaluation, Dynamic Mechanical Analysis (DMA), Thermomechanical Analysis (TMA), Differential Scanning Calorimetry (DSC) as well as Thermogravimetry (TGA). retaining wall inspections. The Thermal Analysis abilities at Westmoreland Mechanical Testing & research published here study, Inc. can strengthen the deepness and also quality of screening results guaranteeing materials have the ability to withstand its designated application.

Our skilled technicians as well as metallurgists function closely with the analytical and also physical screening teams to give a general sight of material characteristics to ensure that also one of the most hard issues can be determined and resolved rapidly. Services consist of, basic microstructure, macro/grain circulation, alpha situation, micro solidity, fractography, grain dimension, IGA/IGO/decaburization and also even more.

Retaining Wall Inspections for Beginners

Westmoreland Mechanical Screening & Study, Inc (WMT&R) is a world class Chemical and Analytical Testing Research laboratory making use of definitive spectrometer modern technology. Operating in combination with ICP and also Graphite Furnace AA makes certain quick turn-around by getting rid of the demand for prolonged damp chemical examinations. These cutting-edge systems supply boosted evaluation speed, element ranges, as well as level of sensitivity.Westmoreland Mechanical Testing & Research, Inc (WMT&R) has an international reputation for trustworthy crack durability testing. The cutting edge fracture laboratory is designed for the high volume, fast turn-around jobs required by the aerospace, vehicle, power generation, oil & gas, additive manufacturing and clinical industries. WMT&R's fracture toughness and also exhaustion materials testing research laboratory residences a large variety of equipment as well as fixtures efficient in 1 million lb.

Testing consists of ASTM E399 which offers disc shape, arc stress, arc bend, single-edge bend, and small stress. Concerning portable stress testing, WMT&R is geared up to do materials evaluating on dimensions varying from.

Excitement About Retaining Wall Inspections

With over half a century of products checking experience, and also essential Nadcap and also A2LA certifications, Westmoreland Mechanical Screening & Research Study, Inc (WMT&R) is uniquely qualified to test materials developed using additive manufacturing procedures. Westmoreland Mechanical Screening & Research Study, Inc (WMT&R) is a trusted materials evaluating partner for the Click This Link aerospace primes More Help and various other firms in innovative sectors such as vehicle, medical, and also power generation that are leading the fostering of these products as well as processes.Products screening, measurement of the qualities and actions of such compounds as metals, porcelains, or plastics under different problems. The data hence acquired can be made use of in specifying the viability of materials for numerous applicationse.

For suppliers, it is of the utmost relevance to comprehend the mechanical properties of products that exhibit some Hookean actions during loading. It is necessary since the efficiency of a structure is regularly figured out by the amount of deformation permitted. Materials are examined for diverse functions: to identify the properties of the raw material, to inspect top quality at intermediate phases in production processes, to inspect end products, as well as to assist research.

Report this wiki page